Strive to meet the highest standards

Make sure you comply with the latest hygiene requirements

All process industries are subject to increasing regulatory requirements which increases the focus on resource consumption, product safety and official hygienic certifications.

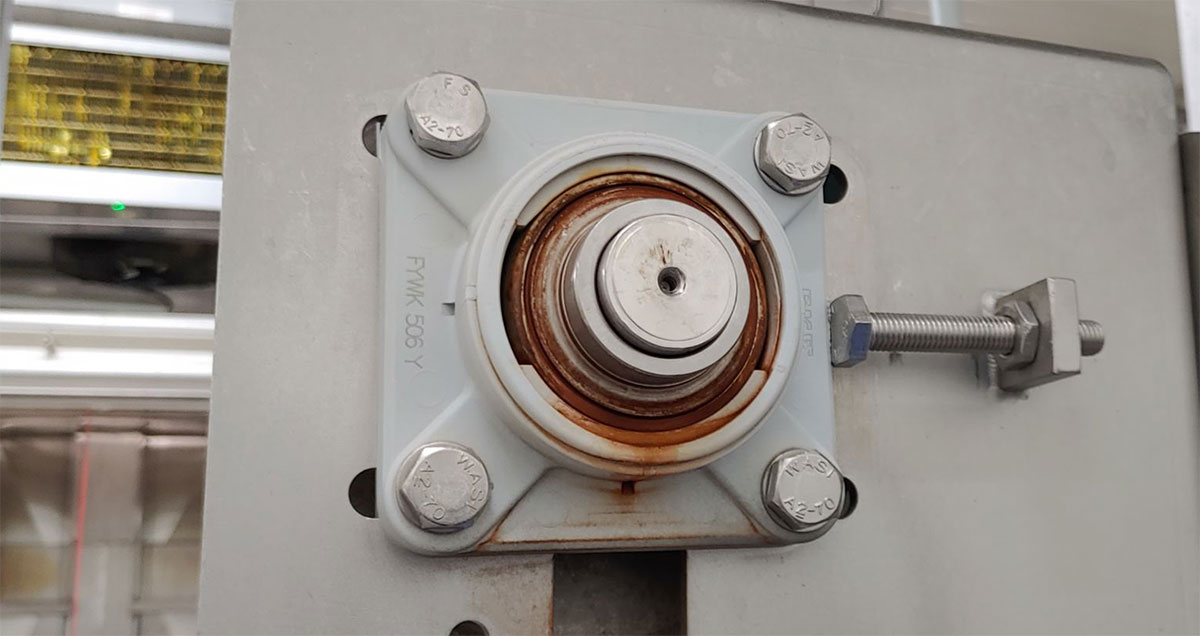

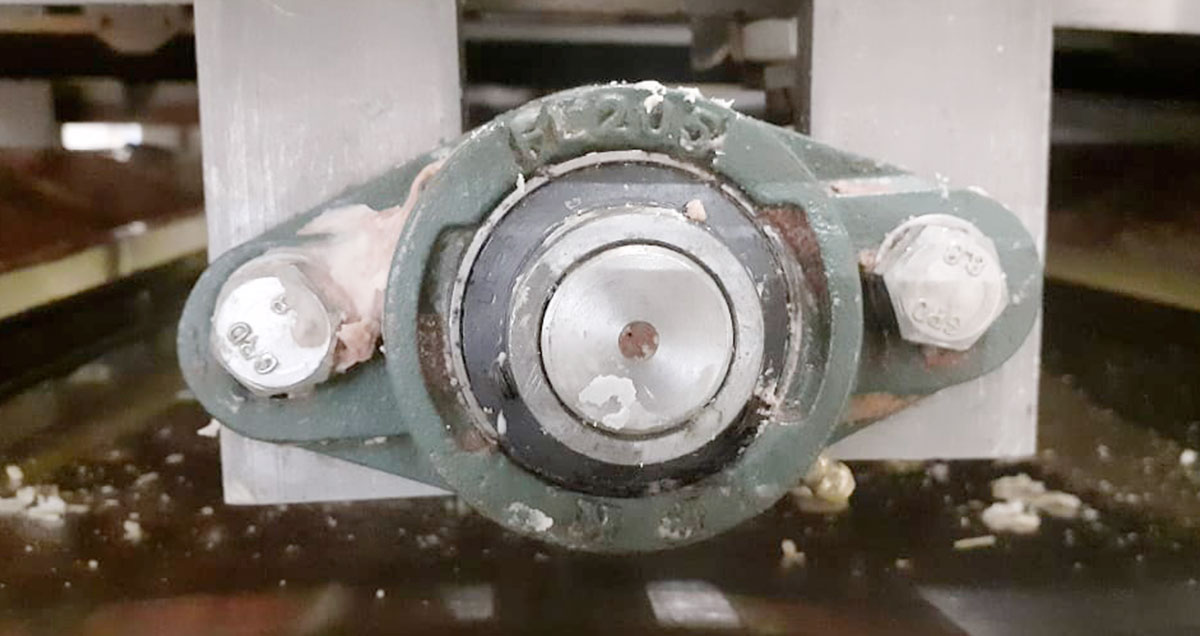

NGI is the only company in the world that is able to offer levelling feet and bearing houses with 3-A, EHEDG, and USDA-certification. Our certified hygienic and patented products are the optimal choice for machinery that has to comply with strict hygiene requirements.